Ukukhetha ekunenehex bolt kunye natiibalulekile ekuqinisekiseni ubude bexesha lezixhobo zokwakha. Ukukhetha okungalunganga kunokukhokelela ekuhanjisweni komthwalo wentambo ongalinganiyo, njengoko kugxininiswe kuphononongo lukaMotosh, oluchonge izinto ezithambileyo ze nut njengento enegalelo. Uvavanyo lokudinwa kukaKazemi luphinde lwatyhila ukuba ukulayisha okuninzi kwe-axial kunciphisa kakhulu ubomi bebholithi, kugxininisa ukubaluleka kwemathiriyeli kunye noyilo. Iifasteners ezikumgangatho ophezulu, ezifanalima ibhawudi kunye nendongomane, umkhondo bolt kunye nut, okanyeibholithi yecandelo kunye ne nut, ukuthintela ukungaphumeleli rhoqo, ukonga iindleko ngexesha. Ukukhetha okufanelekileyo kwandisa ukuqina, kunciphisa ukugcinwa, kunye nokwandisa ukusebenza kwiindawo ezifunayo.

Izinto eziphambili zokuThatha

- Ukukhetha iimathiriyeli elungileyo kwiibholithikunye namandongomane kubalulekile. Insimbi engenasici iyamelana nomhlwa kakuhle, ngelixa intsimbi yekhabhoni inexabiso eliphantsi kwaye yomelele.

- Ukwazi imida yomthwalo ngundoqo kukhuseleko. Ngalo lonke ixesha khetha iziqhoboshi ezidibana okanye ezihamba ngaphaya komthwalo ofunekayo womsebenzi wakho wokwakha.

- Ubungakanani obuchanekileyo kunye nodidi lwentambo yenza imidibaniso eyomeleleyo. Sebenzisa iitshathi zobungakanani kunye nezixhobo ezifana neerula ukujonga imilinganiselo phambi kokuba uzisebenzise.

- Ukuthengaiziqhoboshi zomgangatho olungileyoigcina imali ngokuhamba kwexesha. Izinto ezomeleleyo zifuna ukulungiswa okuncinci kwaye zigcine izixhobo zisebenza ixesha elide.

- Ukujonga izinto zokubopha kudla ngokunceda ukuphepha iingxaki. Jonga umonakalo, umhlwa, kunye namandla afanelekileyo omthwalo ukugcina izixhobo zakho zokwakha zikhuselekile.

Ukukhethwa kwezinto eziphathekayo kwi-Hex Bolt kunye neNut

Izixhobo eziqhelekileyo kunye neePropati zazo

Ukukhetha imathiriyeli efanelekileyokwi-hex bolt kunye ne-nut ibalulekile ekuqinisekiseni ukuqina kunye nokusebenza kwizicelo zokwakha. Isixhobo ngasinye sinikezela ngeempawu ezizodwa ezenza ukuba zilungele ukusetyenziswa okuthe ngqo. Ngezantsi luthelekiso lwezixhobo ezisetyenziswa ngokuqhelekileyo:

| Izinto eziphathekayo | Iingenelo | Iingxaki |

|---|---|---|

| Yenziwe ngentsimbi eshayinayo | Ukumelana nokugqwesa okugqwesileyo; ilungele izicelo zangaphandle naselwandle | Ixabiso elingaphezulu kuneentsimbi eziqhelekileyo |

| Intsimbi yeCarbon | Yomelele kwaye yomelele; isebenza kakuhle emalini | Inokufuna iingubo zokukhusela umhlwa |

| I-Titanium | Umlinganiselo ogqwesileyo wamandla-kubunzima; ilungele iimeko ezingqongileyo ezigqithisileyo | Iindleko eziphezulu; ayinakusetyenziswa ngokubanzi |

Intsimbi engatyiwayo igqame ngokuxhathisa ukuthotywa kwayo, iyenza ilungele indawo engaphandle naselwandle. I-Carbon steel, ngakolunye uhlangothi, iyindlela engabizi kakhulu enika amandla kunye nokuqina kodwa isoloko ifuna iingubo ezongezelelweyo zokukhusela i-rust. I-Titanium, nangona ingaxhaphakanga kangako, inika umyinge wamandla-kubunzima obukhethekileyo, iyenza ilungele iimeko ezinzima.

Ukuqonda ezi zakhiwo kunceda ekukhetheni izinto ezifanelekileyo kakhulu kwi-hex bolt kunye ne-nut, ukuqinisekisa ukuba i-fasteners ihlangabezana neemfuno zendawo yokwakha.

Ukukhetha iMathiriyeli yeeNdawo eziKhethekileyo

Imeko-bume apho i-hex bolt kunye ne-nut iya kusetyenziswa kakhulu kunempembelelo enkulu ekukhethweni kwezinto. Kwizicelo zangaphandle okanye zaselwandle, insimbi engenasici idla ngokuba yinto ekhethwayo ngenxa yomgangatho wayo okhuselayo we-oxide okhusela i-oxidation kunye ne-corrosion. Olu phawu luphucula ixesha elide kwaye lunciphisa iindleko zokugcinwa kwexesha.

Kwiindawo ezinobushushu obuphezulu okanye obunobuchwephesha bekhemikhali, intsimbi ye-alloy ene-coating emnyama iyasebenza kakhulu. I-coating ayiphuculi kuphela ukuxhathisa ukubola kodwa yonyusa ukomelela kweqondo lobushushu, iyenze ilungele izicelo ezibangwayo. Ngeenjongo zokwakha ngokubanzi, i-carbon steel ihlala ithandwa kakhulu ngenxa yokufikeleleka kwayo kunye nokuguquguquka, nangona inokufuna i-galvanization okanye i-zinc plating yokukhusela okongeziweyo.

Ingcebiso: Soloko uqwalasela iimeko zokusingqongileyo, ezifana nokufuma, ubushushu, kunye nokuvezwa kwimichiza, xa ukhetha imathiriyeli yeebholiti zehex kunye namandongomane. Oku kuqinisekisa ukuba iifasteners zigcina ingqibelelo kunye nokusebenza kwazo ngexesha.

Izibonelelo zeNtsimbi eNgatyiwayo, iNtsimbi yeCarbon, kunye neNtsimbi yeAlloy

Isixhobo ngasinye sibonelela ngeengenelo ezahlukeneyo ezihlangabezana neemfuno ezahlukeneyo zokwakha:

- Yenziwe ngentsimbi eshayinayo: Eyaziwayo ngokuxhathisa okungaqhelekanga kwe-corrosion, i-akhawunti yensimbi engenasici ngaphezu kwe-30% yazo zonke izibophelelo ezisetyenziselwa ukwakha. Ubungakanani bayo obuphezulu bobunzima bobunzima buvumela izakhiwo ezilula, ukunciphisa ukusetyenziswa kwezinto kunye nefuthe lokusingqongileyo. Ukongezelela, ukuqina kwayo kukhokelela kwiindleko zokugcinwa okuphantsi, okwenza kube yinto ebiza imali ekhethiweyo ekuhambeni kwexesha.

- Intsimbi yeCarbon: Le nto isetyenziswa ngokubanzi ekwakheni ngenxa yamandla ayo kunye nokufikeleleka. Ilungele izicelo apho iindleko ziyinkxalabo kodwa amandla akanako ukuthotywa. Ngeengubo ezifanelekileyo, i-carbon steel fasteners inokumelana neemeko ezinzima, iqinisekisa ubomi obude.

- Intsimbi yentsimbi: Ukubonelela ngeepropathi eziphuculweyo zoomatshini, intsimbi yealloyi ifanelekile kwizicelo ezifunayo. Yaloukuqina okuphezulu kunye nokuqina kwemvelisoyenze ilungele oomatshini abanzima kunye namalungu olwakhiwo. Uyilo lwamantongomane amade kwi-alloy steel fasteners kunciphisa uxinzelelo kwimicu, ukwandisa amandla okudibanisa kunye nokuzinza.

Ngokuqonda izibonelelo zezi zixhobo, iingcali zokwakha zinokwenza izigqibo ezinolwazi eziphucula ukusebenza kunye nobomi obude bezixhobo zabo.

Ukuvavanya amandla kunye nomthamo womthwalo

Ukuqonda Amanqaku omthwalo

Amazinga omthwalo amisela amandla aphezulu e-hex bolt kunye ne-nut enokumelana ngaphandle kokusilela. Ezi zilinganiso zibalulekile ekuqinisekiseni ukhuseleko nokuthembeka kwezixhobo zokwakha. Iinjineli zibala iireyithingi zomthwalo ngokusekwe kwizinto ezinje ngokuqina kwezinto, ubungakanani bebholithi, kunye noyilo lwentambo. Kwizicelo zokwakha ezinzima, i-fasteners kufuneka ihlangabezane neemfuneko ezithile zobungqina kunye nobunzima bokusingatha uxinzelelo olunzulu.

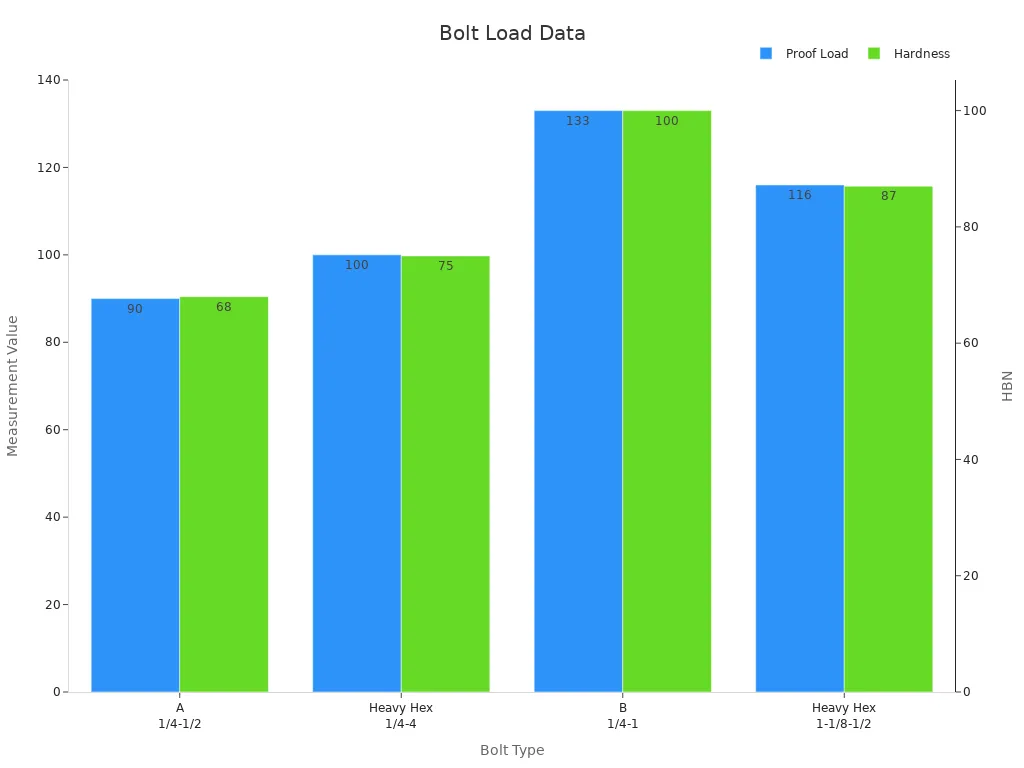

Itheyibhile engezantsi iqaqambisa ubungqina bomthwalo kunye nedatha yobulukhuni kumabakala ahlukeneyo kunye nezimbo zehex bolt kunye namantongomane:

| IBanga | Isimbo | Ubungakanani (ngaphakathi) | Umthwalo wobungqina (ksi) | Ukuqina (HBN) |

|---|---|---|---|---|

| A | Hex | 1/4 - 1-1/2 | 90 | 68 |

| Hex Heavy | 1/4 – 4 | 100 | 75 | |

| B | Hex Heavy | 1/4 – 1 | 133 | 100 |

| Hex Heavy | 1-1/8 - 1-1/2 | 116 | 87 |

Phawula: Heavy hex nuts are thicker than standard hex nuts, inika ubungqina bomthwalo ophezulu amandla ngokwemigangatho ASTM A563.

Ukuqonda olu linganiso kunceda iingcali zokwakha zikhethe iziqhoboshi ezihambelana neemfuno zoomatshini zezixhobo zabo, ziqinisekisa ukuqina kunye nokhuseleko.

Imigangatho yoShishino lweeFasteners zamandla aphezulu

Imigangatho yoShishino idlala indima ebalulekileyo ekuchazeni ukusebenza kunye nokuthembeka kwezibophelelo eziphezulu. Le migangatho iqinisekisa ukungaguquguquki kwimveliso kwaye ibonelele ngebenchmarks zokuvavanya amandla okuqina, ukuqina, kunye nokuqina. Apha ngezantsi kukho imigangatho ephambili yeebholiti zehex kunye namantongomane asetyenziswa ekwakhiweni:

| Umgangatho | Inkcazo | Ubuncinci bokuqina kokuqina |

|---|---|---|

| A354-17e2 | Iibholiti zentsimbi ezicinyiweyo kunye ne-Tempered Alloy, i-Studs, kunye neFasteners | N / A |

| F2882/F2882M-17 | I-alloy Steel Screws, Ubushushu bunyangwa | 170 ksi / 1170 MPa |

| F3125/F3125M-25 | Iibholiti zoLwakhiwo oluPhezulu kunye neeNdibano | 120 ksi, 144 ksi, 150 ksi / 830 MPa, 1040 MPa |

| F3043-23 | Ukujija IiNdibano zeBolt yesakhiwo soLawulo lweTension | 200 ksi |

| F3111-23 | IiNdibano zeBolt/Nut/Iwasher enzima | 200 ksi |

| F3148-17a(2024) | IiNdibano zeBolt zoLwakhiwo oluPhezulu | 144 ksi |

Le migangatho, efana ne-ASTM F3125 kunye ne-F3043, iqinisekisa ukuba i-fasteners ihlangabezana neemfuno zoomatshini kwizicelo ezinzima. Iingcali zokwakha kufuneka zihlale ziqinisekisa ukuthotyelwa kwale migangatho xa ukhetha izinto zokubopha kwiiprojekthi ezibalulekileyo.

Izicelo ezifuna i-Hex Bolts kunye ne-Nuts zamandla aphezulu

I-hex bolts kunye namantongomane aphezulu ayimfuneko kwizicelo apho kukho imithwalo enzima kunye neemeko ezinzima. Ezi fasteners ziqhele ukusetyenziswa kwi:

- Uqhagamshelo lwentsimbi yesakhiwo: Iibholiti eziphakamileyo ezikhuselekileyo ezikhuselekileyo kunye neentsika kwizakhiwo kunye neebhuloho, ziqinisekisa ukuzinza phantsi kwemithwalo eguquguqukayo.

- Oomatshini abanzima: Izixhobo ezinje ngee-excavators kunye neecranes zixhomekeke kwizibophelelo ezihlala ixesha elide ukujongana noxinzelelo lokusebenza kunye nokungcangcazela.

- Izityalo zoShishino: Izixhobo ezinobushushu obuphezulu okanye ubume bendawo ebolileyo zifuna iziqhoboshi ezenziwe ngentsimbi yealloyi okanye insimbi engenasici ukwenzela ukusebenza okuphuculweyo.

- Ulwakhiwo lwaseLwandle: Izibophelelo zentsimbi engatyiwayo ziyaxhathisa ukubola kwindawo ezihlala amanzi anetyuwa, zizenza zilungele iidokhi kunye namaqonga angaphesheya konxweme.

Itshathi engezantsi ibonisa ubudlelwane phakathi komthwalo wobungqina kunye nobunzima bamabanga ahlukeneyo ebholiti, igxininisa ukubaluleka kokukhetha isibophelelo esifanelekileyo kwizicelo ezithile:

Ukukhetha i-hex bolt efanelekileyo kunye namantongomane kwezi zicelo kuqinisekisa ubomi obude kunye nokhuseleko lweizixhobo zokwakha. Iingcali kufuneka zithathele ingqalelo iireyithingi zomthwalo, imigangatho yoshishino, kunye neemeko zokusingqongileyo ukwenza izigqibo ezinolwazi.

Ubungakanani kunye neeNkcazo zeMisonto

Ukukhetha ubungakanani obuchanekileyo beSixhobo soKwakha

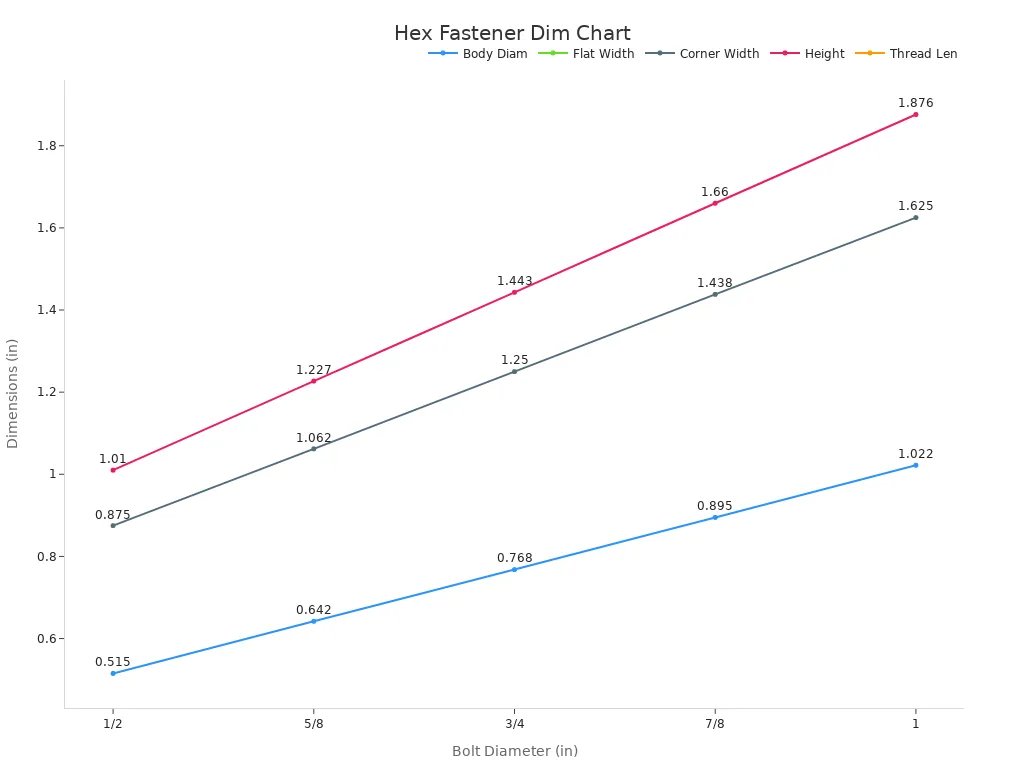

Ukukhetha ubungakanani obuchanekileyo be-hex bolt kunye ne-nut kubalulekile ekuqinisekiseni uqhagamshelwano olukhuselekileyo noluthembekileyo kwizixhobo zokwakha. Ubungakanani buchaphazela ngokuthe ngqo ukukwazi kwesiqhoboshi sokuphatha imithwalo kunye nokugcina imfezeko yesakhiwo. Iitshathi ezinobungakanani kunye neenkcukacha zokunyamezela zinika isikhokelo esixabisekileyo sokukhetha ubungakanani obufanelekileyo. Itheyibhile engezantsi ichaza imilinganiselo ephambili yezibophelelo zeheksi:

| I-Bolt Diameter | Ububanzi bomzimba | Ububanzi ngapha kweeFlethi | Ububanzi ngapha kweekona | Ubude | Ubude bemisonto |

|---|---|---|---|---|---|

| 1/2 | 0.515 | 7/8 | 0.875 | 1.010 | 5/16 |

| 5/8 | 0.642 | 11/16 | 1.062 | 1.227 | 25/64 |

| 3/4 | 0.768 | 11/4 | 1.250 | 1.443 | 15/32 |

| 7/8 | 0.895 | 17/16 | 1.438 | 1.660 | 35/64 |

| 1 | 1.022 | 15/8 | 1.625 | 1.876 | 39/64 |

Ingcebiso: Soloko ubhekisa kwiitshathi ezinobukhulu ukuqinisekisa ukuba isiqhoboshi esikhethiweyo siyahambelana neemfuno zesixhobo.

I-Thread Pitch kunye nokuQwalasela okuLungileyo

Isandi somsonto kunye nokulinganadlala indima ebalulekileyo ekuhambelaneni kwe-hex bolts kunye namantongomane. Ubungakanani bomsonto bubhekisa kumgama ophakathi kwemisonto, ngelixa ukulingana kuqinisekisa ukuba ibholithi kunye namantongomane zidibana kangakanani na. Ukungalingani kwipitch yentambo kunokukhokelela ekubopheni okungafanelekanga, ukunciphisa amandla oqhagamshelwano. Kwizixhobo zokwakha, iintambo ezirhabaxa zihlala zikhethwa ngenxa yokumelana nokukhululwa kunye nokulula kokuhlanganisa.

Itshathi engezantsi ibonisa unxulumano phakathi kwedayamitha yebholithi kunye nemilinganiselo yomsonto, inceda iingcali ukuba zikhethe ukulingana okufanelekileyo kwizicelo zazo:

Ukulinganisa kunye nokuTshatisa iiBolts zeHex kunye neeNti

Imilinganiselo echanekileyo ibalulekile ekuthelekiseni i-hex bolts kunye namandongomane. Ukusebenzisa izixhobo ezifanelekileyo kuqinisekisa ukulungelelaniswa okufanelekileyo kwaye kuthintela ukusilela komatshini. Izixhobo ezicetyiswayo ziquka:

- IiCalipers: Ukulinganisa ububanzi, ubude, kunye nobukhulu bentloko ngokuchanekileyo.

- I-Tread Gauge: Qinisekisa i-pitch yentambo ukuqinisekisa ukuhambelana.

- Umlawuli okanye umlinganiselo weTape: Ukulinganisa ngokukhawuleza ubude obupheleleyo beebholiti.

Ukulinganisa ezi zixhobo kubalulekile ukugcina ukuchaneka. Izixhobo zokulinganisa rhoqo zinciphisa iimpazamo, ziqinisekisa ukuba i-fasteners ihlangabezana neenkcukacha ezifunekayo.

Ingcebiso yePro: Soloko uqinisekisa imilinganiselo phambi kofakelo ukunqanda iziqhoboshi ezingahambelaniyo, ezinokubeka esichengeni ukhuseleko lwezixhobo.

Iingubo kunye nokuGqibela uKuhlala ixesha elide

Ukubaluleka koKuxhathisa iCorrosion

Ukumelana nomhlwa kudlala indima ebalulekileyo ekwandiseni ubomi beziqhoboshi ezisetyenziswa kwizixhobo zokwakha. Imiba yokusingqongileyo efana nokufuma, ukuguquguquka kobushushu, kunye nokuchanabeka kwimichiza kunokukhawulezisa ukuwohloka kwezibophelelo. Iziqhoboshi ezonakeleyo zibeka emngciphekweni ukuthembeka kolwakhiwo lwezixhobo, nto leyo ekhokelela ekusilelekeni okunokwenzeka kunye nokulungiswa kweendleko. Ukukhethaiingubo ezibonelela ngokhuseleko olusebenzayo lomhlwaiqinisekisa ukuba iziqhoboshi zigcina amandla kunye nokusebenza kwazo ekuhambeni kwexesha.

Ngokomzekelo, kwiindawo ezingaphandle, izibophelelo zihlala zisesichengeni semvula, ukufuma kunye nongcoliseko. Iingubo zisebenza njengesithintelo sokukhusela, ukuthintela i-oxidation kunye nokubunjwa kwe-rust. Oku kubaluleke ngakumbi kwi-hex bolt kunye ne nut, njengoko la malungu abaluleke kakhulu ekubambeni oomatshini abanzima kunye nezakhiwo kunye. Ngokubeka phambili ukuxhathisa umhlwa, iingcali zokwakha zinokunciphisa iimfuno zokulondolozwa kunye nokuphucula ukuthembeka kwezixhobo.

Ukuthelekisa iZinc Plating, Galvanization, kunye nezinye iiCoatings

Iingubo ezahlukeneyo zibonelela ngeenzuzo ezizodwa kwaye zifanelekile kwizicelo ezithile. Itheyibhile engezantsi igxininisa iimpawu eziphambili kunye nokusetyenziswa kweengubo eziqhelekileyo:

| Uhlobo lokugquma | Ezona mpawu | Usetyenziso |

|---|---|---|

| Iingubo zeZinc | Ukukhuselwa kwe-corrosion yedini, ukuchasana okugqwesileyo kwe-atmospheric, indleko-esebenzayo | Iimoto, ulwakhiwo, izixhobo ezinzima |

| Iingubo zePhosphate | Isithintelo ngokuchasene nomhlwa, siphucula ukunamathela kwepeyinti, ukuxhathisa ukunxiba okuphakathi | Amacandelo afuna ukuqhubeka okanye ukugqitywa, apho ukunamathela kwepeyinti kubalulekile |

Iingubo ze-Zinc zibonelela ngokukhuselwa kwedini, okuthetha ukuba zenza umhlwa endaweni yesiqhoboshi, ngaloo ndlela sandisa ubomi baso. Oku kubenza balungele ukwakhiwa ngokubanzi kunye nezixhobo ezinzima. Ngakolunye uhlangothi, iingubo ze-phosphate zenza umqobo ngokuchasene nokubola kunye nokuphucula ukunamathela kwepeyinti, okwenza kube lula kumacandelo afuna ukugqitywa okongeziweyo.

Xa uthelekisa i-zinc plating kunye ne-galvanization, iimethrikhi zokusebenza zityhila umahluko obonakalayo wokuqina. Iingubo ezifakwe ngokufanelekileyo zegalvanized zingahlala ngaphezu kweminyaka engama-50 kwimimandla yasemaphandleni kunye ne-20 ukuya kwi-50 iminyaka kwiindawo zoshishino. I-Zinc plating, ngelixa ingabizi kakhulu, isenokungasebenzi kakuhle kwiimeko ezinzima ezifana neendawo zaselwandle, apho ukufuma okuphezulu kunye netyuwa kukhawulezisa ukubola. Izinto ezifana nobukhulu bokugquma, ukuvezwa kokusingqongileyo, kunye neendlela zokuzigcina zikwaphembelela ubomi obude bezi zigqibo.

Iindleko zokulinganisa kunye noMgangatho

IiNzuzo zeXesha elide zeFasteners ezikwiMgangatho oPhezulu

Utyalo-mali kwiiifasteners ezikumgangatho ophezuluibonelela ngeenzuzo ezibalulekileyo zexesha elide zezixhobo zokwakha. Uvavanyo lomjikelo wobomi (LCA) kunye nohlalutyo lweendleko lubonisa ukuba i-premium fasteners inciphisa ukugcinwa kunye neendleko zokusebenza ngexesha. Umzekelo, iziqhoboshi ezisetyenziswa kwiifom zekhonkrithi ezigqumayo (ICFs) zinegalelo kumaxabiso aphantsi amandla kunye nokuqina okuphuculweyo. Ngelixa iindleko zokuqala zeziqhoboshi ezikumgangatho ophezulu zinokubonakala ziphezulu, amandla azo okumelana nokunxiba kunye noxinzelelo lwendalo esingqongileyo kunciphisa isidingo sokutshintshwa rhoqo. Oku kuhlala konga imali kuphela kodwa kunciphisa ixesha lokungasebenzi, ukuqinisekisa ukuba iiprojekthi zokwakha zihlala zicwangcisiwe. Ngaphaya koko, isigaba sokusebenza sezixhobo zokwakha senza ngaphezulu kwe-90% yefuthe laso lokusingqongileyo. Ngokukhetha izixhobo ezithembekileyo, iingcali zinokomeleza uzinzo ngelixa zifezekisa iindleko ezifanelekileyo.

Ukuphepha Umgangatho Ophantsi, Iinketho ezingabizi kakhulu

Iifasteners ezinexabiso eliphantsi zihlala zibonakala zinomtsalane ngenxa yokufikeleleka kwazo, kodwa zinokukhokelela kwimiba ebalulekileyo. Ezi zibophelelo zidla ngokuswela amandla kunye nokuqina okufunekayo kwimisebenzi enzima. Ekuhambeni kwexesha, zisenokugqwala, zikhulule, okanye zisilele phantsi koxinzelelo, zibeke esichengeni ukhuseleko nokusebenza kwezixhobo zokwakha. Ukutshintshwa rhoqo kunye nokulungiswa okuhambelana nezibophelelo ezinomgangatho ophantsi kwandisa iindleko zizonke kunye nokuphazamisa ukusebenza. Ukongeza, izinto ezikumgangatho ophantsi zinokubangela ukuhanjiswa komthwalo ongalinganiyo, okukhawulezisa ukunxiba kumacandelo ezixhobo. Iingcali kufuneka zibeke phambiliumgangatho phezu kweendlekoukuphepha le migibe kunye nokuqinisekisa ubomi obude koomatshini babo.

UkuKhetha okuSebenzayo ngeendleko zeSixhobo soKwakha Ubomi obude

Izisombululo ezingabizi kakhulu azisoloko zithetha ukukhetha eyona ndlela inexabiso eliphantsi. Endaweni yoko, zibandakanya ukukhetha izixhobo kunye nezenzo ezilinganisa ukufikeleleka kunye nokusebenza. Uphando lwemarike luqaqambisa iindlela ezininzi zokuphumeza olu lungelelwano:

- Ukuhlaziywa kwezixhobo kwandisa ixesha lokuphila koomatshini, ukunciphisa imfuno yokwenziwa kwemveliso entsha.

- Ukuphucula izixhobo ezidala kuphucula ukusebenza kakuhle kwamandla kwaye kwehlisa ukusetyenziswa kwamafutha.

- Ukurisayikilisha nokulahlwa ngendlela eyiyo kwemathiriyeli kukhuthaza ulawulo lwenkunkuma nozinzo.

- Ukufumana uxanduva lweefasteners kuqinisekisa ukuhlala ngaphandle kokubeka esichengeni imiqobo yohlahlo lwabiwo-mali.

Ngokwamkela olu qheliselo, iingcali zokwakha zinokuphucula ixesha elide lezixhobo zabo ngelixa begcina iindleko ezifanelekileyo. Ukukhetha i-hex bolt efanelekileyo kunye namantongomane, umzekelo, kuqinisekisa ukusebenza okuthembekileyo kwaye kunciphisa amathuba okungaphumeleli okungalindelekanga.

Ukuphepha Iimpazamo Eziqhelekileyo

Ukuthintela Izixhobo Ezingahambelaniyo

Ukusebenzisaizixhobo ezingahambelaniyokuba iibholiti ze-hex kunye namantongomane zinokukhokelela ekunxibeni kwangaphambi kwexesha, ukubola, okanye ukusilela. Iingcali zokwakha kufuneka ziqinisekise ukuhambelana kwezinto eziphathekayo ukugcina ingqibelelo yeefasteners. Ngokomzekelo, ukudibanisa i-bolt yensimbi engenasici kunye ne-carbon steel nut kunokubangela i-galvanic corrosion, ngakumbi kwiindawo ezimanzi okanye zaselwandle. Oku kwenzeka xa iintsimbi ezimbini ezingafaniyo zidibana, zenza i-electrochemical reaction.

Ukuthintela ukungafani, iingcali kufuneka:

- Tshatisa izinto ezinokumelana ne-corrosion efanayo.

- Qinisekisa amabakala ezinto eziphathekayo kunye neenkcukacha phambi kokufakwa.

- Sebenzisa indibaniselwano ecetyiswa ngumvelisi ukuze usebenze kakuhle.

Ingcebiso: Soloko ujonga iitshathi zokuhambelana kwezinto ukunqanda iimpazamo ezibiza imali eninzi kwaye uqinisekise uqhagamshelo oluhlala ixesha elide.

Ukuqinisekisa ubungakanani bomthwalo ofanelekileyo

AyifanelekangaUkukhetha umthamo womthwaloyimpazamo eqhelekileyo ebeka esichengeni ukhuseleko kunye nokusebenza kwezixhobo. Iibholiti ze-Hex kunye namantongomane kufuneka zimelane nemikhosi eyenziwa ngexesha lokusebenza ngaphandle kokukhubazeka okanye ukusilela. Ukukhetha iziqhoboshi ezinobungqina obungonelanga okanye amandla okuqina kunokukhokelela kukusilela okuyintlekele.

Iingcali kufuneka:

- Bala ubuninzi beemfuno zomthwalo wesicelo.

- Jonga kwimigangatho yoshishino, efana ne-ASTM okanye i-ISO, ukufumana amaxabiso omthwalo.

- Khetha iziqhoboshi ezinomda wokhuseleko ukuze uphendule ngoxinzelelo olungalindelekanga.

Phawula: Izibophelelo zokulayisha ngaphezulu zingabangela ukuhluthwa kwentambo okanye ukunyuswa kwebholiti, ukunciphisa ukuzinza ngokubanzi koqhagamshelwano.

Unikelo-ngxelo lwemiba yokusiNgqongileyo

Ukungahoyi iimeko zokusingqongileyo ngexesha lokukhetha i-fastener kunokubangela ukubola, ukunciphisa amandla, okanye ukungaphumeleli komatshini. Iindawo zokwakha zihlala zibeka esichengeni iziqhoboshi kumanzi, imichiza, kunye nokuguquguquka kweqondo lobushushu, nto leyo enokuthoba imathiriyeli ngokuhamba kwexesha.

Ukujongana neemeko zokusingqongileyo:

- Sebenzisa izinto zokugquma ezinganyangekiyo kwi-corrosion, ezifana ne-galvanization okanye i-zinc plating, kwiimeko ezifumileyo okanye ezimanzi.

- Khetha intsimbi engenastainless okanye ialloy steel ukwenzela ubushushu obuphezulu okanye ubume bemichiza enobundlobongela.

- Zihlole rhoqo iimpawu zokunxiba okanye ukubola.

Ingcebiso yePro: Qwalasela imiceli mngeni ethile yokusingqongileyo yesiza seprojekthi ukuqinisekisa ukuba iziqinisekiso zigcina ukusebenza kwazo kunye nobomi obude.

Ukukhetha i-hex bolt efanelekileyo kunye ne nut kubalulekile ekuqinisekiseni ixesha elide kunye nokusebenza kwezixhobo zokwakha. Izinto eziphathekayo, amandla, ubungakanani, iingubo, kunye neendleko zonke zidlala indima ebalulekileyo ekuqinisekiseni ukuthembeka kweefasteners. Izibophelelo ezikumgangatho ophezulu azigcini nje ukwandisa imfezeko yolwakhiwo kodwa zikwanciphisa iimfuno zogcino kunye nexesha lokungasebenzi.

- Imakethi ye-fasteners yemizi-mveliso iqikelelwa ukuba iya kudlula kwi-USD 125 yeebhiliyoni ngo-2029, ibonisa ukubaluleka kwayo okukhulayo kulwakhiwo kunye noomatshini.

- Iingcali zincoma ukuphicothwa rhoqo kunye nokugcinwa kwe-fasteners ukuqinisekisa ukusebenza kakuhle kunye nokuthintela ukungaphumeleli okungalindelekanga.

Ngokubeka phambili umgangatho kunye nokwenza ukhetho olunolwazi, iingcali zinokwandisa ukusebenza kakuhle kwezixhobo kunye nokunciphisa ukuphazamiseka kweendleko.

FAQ

Yeyiphi eyona mathiriyeli ilungileyo yeebholiti zehex kulwakhiwo lwangaphandle?

Insimbi engenasici iyona nto ikhethekileyo yokwakhiwa kwangaphandle. Ukuxhathisa kwayo kwe-corrosion kuqinisekisa ukuhlala kwiimeko ezifumileyo okanye ezimanzi. Kwiiprojekthi ezingabizi kakhulu, i-carbon steel eneengubo ezikhuselayo ezifana ne-galvanization nazo zingenza kakuhle.

Iingcali zinokuqinisekisa njani ukuhambelana okufanelekileyo kwebholithi kunye ne-nut?

Iingcali kufuneka zitshatise imathiriyeli, intambo yokulinganisa, kunye neenkcukacha zobungakanani. Ukusebenzisa izixhobo ezifana neecalipers kunye neegeji zentambo kuqinisekisa imilinganiselo echanekileyo. Iingcebiso zomenzi zikwanceda ukuphepha ukungafani.

Kutheni i-coatings ibalulekile kwi-hex bolts kunye namantongomane?

Iingubo zikhusela i-fasteners kwi-corrosion, zandisa ubomi bazo. I-Zinc plating, i-galvanization, kunye neengubo ze-phosphate zibonelela ngamanqanaba ahlukeneyo okhuseleko. Ukhetho luxhomekeke ekuvezweni kokusingqongileyo kunye neemfuno zesicelo.

Kufuneka zihlolwe kangaphi izibophelelo?

Izibophelelo kufuneka zihlolwe rhoqo, ngakumbi kwiindawo ezinoxinzelelo oluphezulu okanye kwindawo ezonakalisayo. Iitshekhi zenyanga zeempawu zokuguga, ukubola, okanye ukukhulula zinceda ukugcina ukhuseleko lwesixhobo kunye nokusebenza.

Ngaba iziqhoboshi zokuqina eziphezulu ziyimfuneko kuzo zonke izicelo zokwakha?

Izibophelelo eziphezulu zokuqina ziyimfuneko kwimithwalo enzima okanye iimeko ezinzima, ezifana nokudibanisa kwensimbi yesakhiwo okanye oomatshini obunzima. Kwizicelo ezikhaphukhaphu, iifasteners zomgangatho oqhelekileyo zinokwanela, ngaphandle kokuba ziyahlangabezana neemfuno zomthwalo.

Ixesha lokuposa: Apr-25-2025