Amandla aphezuluumkhondo bolt kunye nutiindibano zidlala indima ebaluleke kakhulu ekugcineni uzinzo kunye nokusebenza kweekhareji zangaphantsi. Kwimigodi yobhedu yaseChile, landelela iinkqubo zebholithi kunye namantongomane, ngokunjaloibholithi yecandelo kunye ne nutindibaniselwano, ukunyamezela uxinzelelo olugqithisileyo, oluhlala lufuna ukutshintshwa rhoqo kwiiyure ezingama-800-1,200. Ukongeza,lima ibhawudi kunye nendongomaneIzisombululo zibalulekile kwizicelo zoomatshini abanzima. I-European Machinery Directive 2023 igunyazisa uvavanyo lwe-ultrasonic ukomeleza ukhuseleko, iqaqambisa imfuno ebalulekileyo yeziqhoboshi ezithembekileyo kwimisebenzi efunayo.

Izinto eziphambili zokuThatha

- Iibholiti zomkhondo owomeleleyo kunye namantongomanezibalulekile kwiikhareji zangaphantsi zabarhuqi. Bagcina umkhondo endaweni, ukunceda oomatshini basebenze kakuhle kwiindawo ezinzima.

- Ukujonga iibholithi zengoma kunye namandongomane kaninzi kunokubona umonakalo kwangoko. Ukulungisa iingxaki kwangethuba kuthintela ukulungiswa okuxabisa imali eninzi kwaye kugcine izixhobo zisebenza ngcono.

- Ukusebenzisaizixhobo ezomeleleyo zeebholitikunye namantongomane ehlisa iindleko zokulungisa. Amalungu anzima ahlala ixesha elide, ngoko ke ubeka endaweni yawo kaninzi, ukonga imali kunye nexesha.

Ukuqonda iinqwelo zangaphantsi zeCrawler

Isishwankathelo seCrawler Undercarriages

Iinqwelo zangaphantsi zeCrawler zenza isiseko soomatshini abanzima, zenza intshukumo esebenzayo kwiindawo ezimagqagala. Ezi nkqubo ziquka iingoma, ii-roller, kunye namanye amacandelo enzelwe ukusabalalisa ubunzima ngokulinganayo kunye nokugcina uzinzo. Inkqubela phambili yamva nje kwimakethi ye-crawler track undercarriage iqaqambisa ukwamkelwa kwemathiriyeli ekhaphukhaphu njengentsimbi ephezulu kunye neepolymers eziphambili. Olu tshintsho luphucula ukuqina kunye nokusebenza kakuhle kwamafutha, kuvumela oomatshini ukuba basebenze ngokufanelekileyo kwiindawo ezinomngeni. Ukongeza, ukudityaniswa kwee-sensor ze-IoT zokubeka iliso ngexesha lokwenyani kubonakalisa utshintsho olusiya kumatshini okrelekrele, osebenza ngakumbi. Lo mkhwa ubonakala ngokukodwa kwimimandla ephuhlayo efana ne-Asia-Pacific, apho utyalo-mali lweziseko ezingundoqo luqhuba imfuno yezixhobo ezithembekileyo.

Amacandelo aPhambili kunye neMisebenzi yawo

Iinqwelo zangaphantsi zeCrawler zixhomekeke kwizinto ezininzi ezibalulekileyo ukuqinisekisa ukusebenza kakuhle:

- Iingoma: Ezi zibonelela ngokutsala kunye nenkxaso, zenza ukuba oomatshini banqumle imiphezulu engalinganiyo.

- IiRoller kunye neeIdlers: Ezi zikhokelo kwaye zixhasa amathrekhi, ziqinisekisa ukusebenza kakuhle kunye nokulungelelaniswa okufanelekileyo.

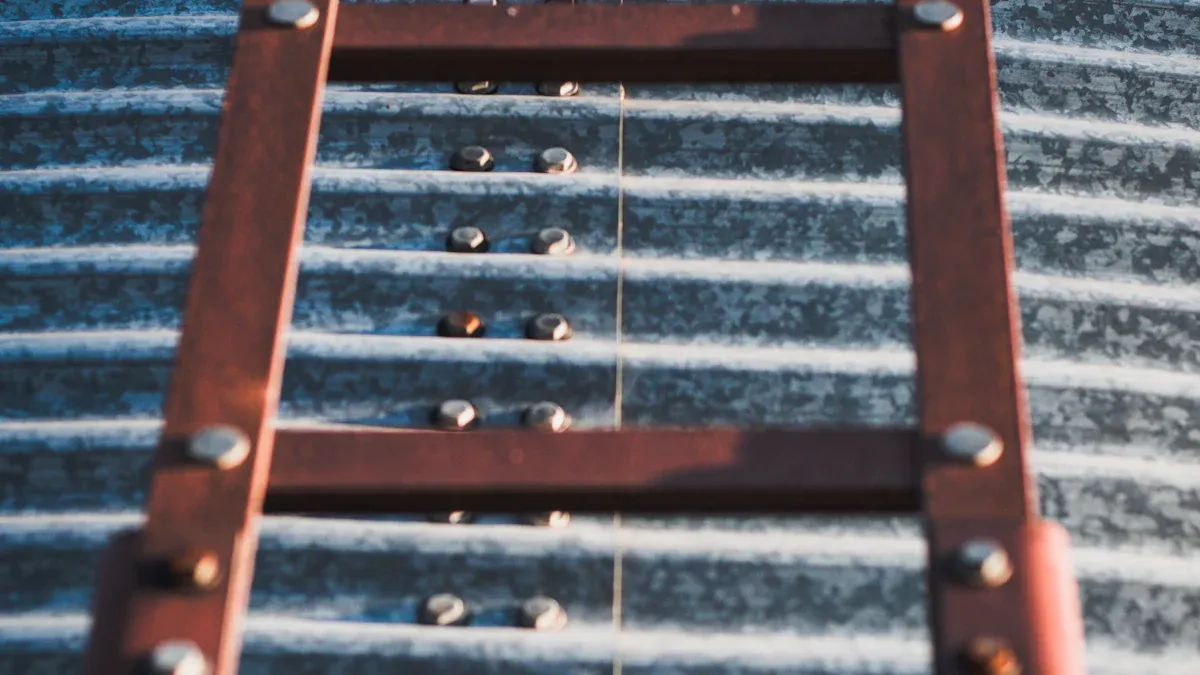

- Landelela iindibano zeBolt kunye neNut: Ezi zikhusela amathrekhi kwi-undercarriage, zigcina ingqibelelo yesakhiwo phantsi kwemithwalo enzima.

- Qhuba Sprockets: La mandla okudlulisa ukusuka enjini ukuya kwimizila, ukuqhubela phambili oomatshini.

Iindlela zokwenziwa ngokwezifiso kushishino zigxininisa izisombululo ezilungiselelwe ukuhlangabezana neemfuno ezithile zokusebenza. Umzekelo, uvavanyo olukhethekileyo lokuziqhelanisa nokusingqongileyo luqinisekisa ukuba amacandelo asebenza ngokuthembekileyo kumaqondo obushushu agqithisileyo okanye iimeko eziyingozi. Uhlolo kunye neenkqubo zovavanyo, ezinjengohlalutyo lokunxiba kunye nokuqinisekiswa kokutywinwa komsebenzi, ziphakamisa ngakumbi ukuqina nokusebenza kakuhle kwezi nkqubo. Ngokuthobela imigangatho yoshishino efana ne-ISO 6014, abavelisi baqinisekisa ukuba iinqwelo zangaphantsi zabarhuqi ziyahlangabezana nemigangatho yokusebenza engqongqo.

Indima ye-Track Bolt kunye neNut kwi-Crawler Undercarriages

Ukuqinisekisa uzinzo kunye neMfezeko yoLwakhiwo

Landela iibholiti kunye namantongomaneisebenza njengomqolo weenqwelo zangaphantsi zabakhasi. Ezi zixhobo zikhusela amathrekhi kwisakhelo se-undercarriage, ukukhusela ukufuduka ngexesha lokusebenza. Oomatshini abanzima bahlala besebenza kwindawo apho umhlaba ongalinganiyo kunye nefuthe lempembelelo ephezulu umngeni kuzinzo. Ngaphandle kweziqhoboshi ezithembekileyo, iitreyi zinokukhulula okanye ziqhawuke, nto leyo ebeka esichengeni amandla omatshini okusebenza ngokukhuselekileyo nangempumelelo.

Abavelisi bayila iibholithi zomkhondo kunye namandongomane ukumelana noxinzelelo olugqithisileyo kunye nokungcangcazela. Izinto eziphezulu eziphezulu, ezifana nentsimbi ye-alloy, ziqinisekisa ukuba ezi zibophelelo zigcina ingqibelelo yazo phantsi kwemithwalo enzima. Ubunjineli obuchanekileyo bonyusa ngakumbi ukusebenza kwabo, kubavumela ukuba baxhathise ukunxiba kunye nokuguqulwa kwexesha.

Ingcebiso:Ukuhlolwa rhoqo kweebholiti zomzila kunye namantongomane kunokunceda ukuchonga iimpawu zokuqala zokuguga okanye ukonakala, ukuqinisekisa ukutshintshwa kwangethuba kunye nokuthintela ukophuka kweendleko.

Igalelo kuSabelo loMthwalo kunye noLungelelwaniso

Iibholithi zomzila kunye namandongomane zidlala indima ebalulekileyo ekusasazeni ubunzima ngokulinganayo kwikhareji yangaphantsi. Ukuhanjiswa komthwalo okufanelekileyo kunciphisa uxinzelelo kumacandelo ngamanye, ukwandisa ubomi babo kunye nokunciphisa umngcipheko wokungaphumeleli komatshini. Ngokukhusela amathrekhi ngokuqinileyo, ezi zibophelelo ziqinisekisa ukuba oomatshini bagcina ulungelelwaniso olufanelekileyo ngexesha lokusebenza.

Iingoma ezingalunganga zingakhokelela ekunxibeni okungalinganiyo, ukunciphisa ukusebenza kakuhle, kunye nokunyuka kokusetyenziswa kwamafutha. Iibholiti zokulandelela kunye namantongomane zithintela imiba enjalo ngokugcina amathrekhi kwindawo yawo ekujoliswe kuyo. Olu lungelelwaniso lubaluleke kakhulu kwizicelo ezifana nemigodi kunye nolwakhiwo, apho oomatshini kufuneka bahambe kwiindawo ezinomngeni ngelixa bethwele imithwalo enzima.

I-bolt yomkhondo egcinwe kakuhle kunye nenkqubo ye-nut inegalelo ekusebenzeni kakuhle kunye nokusebenza okuphuculweyo. Abasebenzisi banokuthembela koomatshini babo ukuba baphathe imisebenzi enzima ngaphandle kokuphazamiseka, ukuphucula imveliso kunye nokhuseleko kwindawo yomsebenzi.

Ukubaluleka kweMathiriyeli yaMandla aphezulu kwiiBolts zeTrack kunye neeNuts

Ukuxhathisa kwimithwalo enzima kunye noxinzelelo

Izinto eziphezulu zamandlaiibholithi zomzila kunye namandongomane zibalulekile ekujonganeni nemithwalo emikhulu kunye noxinzelelo olufunyanwa kwimisebenzi yoomatshini abanzima. Ezi zibophelelo kufuneka zinyamezele uxinzelelo oluqhubekayo oluvela kwiindawo ezingalinganiyo, ukungcangcazela, kunye nobunzima besixhobo ngokwaso. Uvavanyo lwaselabhoratri luqinisekisa ukukwazi kwabo ukumelana namandla anjalo ngovavanyo olungqongqo.

| Uhlobo loVavanyo | Inkcazo |

|---|---|

| Uvavanyo loomatshini | Kubandakanya uvavanyo lomthwalo wobungqina, uvavanyo lwe-tensile, kunye novavanyo lokuqina (i-Rockwell, iBrinell, njl.) |

| Uvavanyo lweMetallurgical | Ibandakanya uvavanyo lobulukhuni obuncinci, uvavanyo lwe-microstructural, kunye nophando lokusilela kwesinyithi |

| Uhlalutyo lweMichiza | Ibandakanya i-ICP / OES kunye nohlalutyo lwe-Spark OES ukuvavanya ukubunjwa kwezinto kunye neempawu |

Ezi mvavanyo ziqinisekisa ukubaumkhondo iibholiti kunye namantongomaneukuhlangabezana nemigangatho yoshishino yokomelela nokuthembeka. Uvavanyo lwarhoqo lweefasteners kunye nemathiriyeli ekrwada kuqinisekisa ukufaneleka kwazo kwindawo ezibangwayo. Uvavanyo lweBolt lukwaqinisekisa ukuba la macandelo anokumelana nomthwalo wawo omiselweyo kwaye asebenze ngokufanelekileyo phantsi koxinzelelo lokusebenza.

Ukuhlala ixesha elide kwiNdawo eziBungqwabalala

Iibholiti zokulandelela kunye namandongomane kufuneka zisebenze ngokuthembekileyo kwiimeko ezigqithisileyo, kubandakanywa amaqondo obushushu aphezulu, iindawo ezitshabalalisayo, kunye nokuba sesichengeni rhoqo kumandla angaphandle. Uvavanyo lwendawo kunye novavanyo lokusingqongileyo lubonisa ukuqina kwazo kwiindawo ezinjalo.

- Uvavanyo olukhoyo lwetorque luvavanya ukuba iziqhoboshi zimelana njani na nokukhululeka ngenxa yokungcangcazela kunye namandla angaphandle.

- Olu vavanyo lubalulekile kumashishini afana nenyukliya, i-aerospace, kunye nezaselwandle, apho ingqibelelo yokuqinisa ikhusela ukusilela okuyintlekele.

- Iziphumo ezivela kolu vavanyo ziqinisekisa ukuba iibholithi zomkhondo kunye namandongomane ahlangabezana nemigangatho esezantsi yezicelo ezijoliswe kuzo, ukunciphisa iziphene kunye nokomeleza ukuqina.

Ngokuchasa ukunxiba kunye nokukhulula, izinto eziphezulu zokomelela zandisa ixesha lokuphila le-bolt kunye neendibano ze-nut. Oku komelela kunciphisa iimfuno zogcino kwaye kuqinisekisa ukuba oomatshini basebenza ngokukhuselekileyo nangokufanelekileyo kwiindawo ezinomngeni.

Izibonelelo zeeBolts zeTrack yamandla aphezulu kunye neeNti

Ukhuseleko olomeleziweyo kunye nokuthembeka

Iibholiti zomkhondo eziphezulu kunye namantongomaneukwandisa kakhulu ukhuseleko kunye nokuthembeka kweekhareji zangaphantsi zabarhuqi. La macandelo aqinisekisa ukuba iingoma zihlala zibotshelelwe ngokukhuselekileyo, naphantsi kweemeko zokusebenza ezigqithisileyo. Ngokuthintela ukufuduswa komkhondo okanye ukugxothwa, banciphisa umngcipheko weengozi kunye nokusilela kwezixhobo.

Ukusetyenziswa kwezinto eziphambili, ezifana nentsimbi ye-alloy, inika ukuchasana okukhethekileyo kuxinzelelo kunye nokungcangcazela. Oku komelela kuqinisekisa ukuba iziqhoboshi zigcina ingqibelelo yazo ekuhambeni kwexesha, nakwiindawo ezinempembelelo ephezulu njengeziza zokwakha okanye imisebenzi yemigodi. Abasebenzisi banokuthemba oomatshini babo ukuba basebenze ngokungaguquguqukiyo, besazi ukuba iibholithi zengoma kunye neendibano zenut ziyilelwe ukujongana nemisebenzi enzima.

Phawula:Ukuhlolwa rhoqo kunye nokuhlolwa kwetorque kuphucula ngakumbi ukhuseleko ngokuchonga imiba enokubakho ngaphambi kokuba inyuke ibe kukungaphumeleli okubalulekileyo.

Ubomi obude beMixholo ye-Undercarriage

Iibholiti zomkhondo eziphezulu kunye namantongomane afaka isandla kwixesha elide lokuphila lamacandelo angaphantsi kwekhareji. Ngokugcina iitreyi ziqinile, zinciphisa ukuhamba okungafunekiyo kunye nokunxiba kwiindawo ezikufutshane, ezinje ngeerola, ii-idlers, kunye ne-sprockets. Oku kuzinza kunciphisa uxinzelelo kumalungu ngamanye, okuwavumela ukuba asebenze ngokufanelekileyo ixesha elide.

Ukuhanjiswa okufanelekileyo komthwalo, okuququzelelwa zezi fasteners, nako kudlala indima ebalulekileyo ekugcineni i-undercarriage. Ukusabalalisa ubunzima obungalinganiyo kunokukhokelela ekugqokeni kwangaphambili kunye nokukrazula, kodwa iibholiti eziphezulu kunye namantongomane aqinisekisa ukuba umthwalo usasazwa ngokulinganayo kuwo wonke inkqubo. Le bhalansi ayiphuculi nje ukusebenza kuphela kodwa iphinda ilibazise imfuno yokutshintshwa kweendleko.

Abavelisi bahlala bencoma ukusebenzisa izibophelelo ezihlangabezana nemigangatho yoshishino ukunyusa ukuqina kwayo yonke indibano ye-undercarriage. Utyalo-mali kwiamacandelo aphezulu-amandlaekugqibeleni igcina ixesha kunye nezixhobo ngokunciphisa ukuphindaphinda ukulungiswa.

Iindleko zokuLondoloza okuPhantsi kunye nexesha lokuphumla

Ukusebenzisa i-bolts ephezulu yamandla kunye namantongomane kunokunciphisa kakhulu iindleko zokugcinwa kunye nokunciphisa ixesha lokuphumla. Ezi zibophelelo zenzelwe ukuba zimelane neemeko ezinzima, zinciphisa ukubakho kokusilela okungalindelekanga. Ngenxa yoko, abaqhubi bachitha ixesha elincinci lokujongana nemiba yoomatshini kunye nexesha elingakumbi lokugxila kwimisebenzi enemveliso.

Ukomelela kwala macandelo kukwaguqulela kutshintsho olumbalwa, nto leyo ethoba iindleko zololongo zizonke. Kumashishini afana nemigodi kunye nokwakha, apho ixesha lokungasebenzi kwezixhobo kunokukhokelela kwilahleko enkulu yemali, oku kuthembeka kubaluleke kakhulu.

Ingcebiso:Ukuphumeza ishedyuli yolungiso olusebenzayo olubandakanya ukuhlolwa rhoqo kwee-bolts zengoma kunye namantongomane kunokunciphisa ngakumbi ixesha lokunciphisa kunye nokuqinisekisa ukusebenza kakuhle.

Ngokukhetha i-fasteners ephezulu, amashishini angakwazi ukufikelela kwi-balance balance phakathi kokusebenza kakuhle kunye nokusebenza kakuhle kweendleko. Olu tyalo-mali aluphuculi nje ukusebenza kweekhareji zangaphantsi ezirhubuluzayo kodwa ikwaxhasa ingeniso yexesha elide.

Ukukhetha kunye nokugcina iiBolts kunye neeNti

Izinto ekufuneka ziqwalaselwe xa ukhetha iiBolts kunye neeNuts zamandla aphezulu

Ukukhetha iibholiti zokuqina okuphezulu kunye namandongomane kubalulekile ekuqinisekiseni ukusebenza kunye nokhuseleko lweekhareji zangaphantsi zabarhuqi. Iikhrayitheriya ezininzi zobugcisa kunye nemigangatho yoshishino ikhokela le nkqubo:

- Ukukhethwa kwezinto: Khetha izinto ezifana nentsimbi, intsimbi engatyiwa, okanye intsimbi yealloyi ukuze ufezekiseamandla aphezulukunye nokuqina.

- Iinketho zoKwaleka: Sebenzisa iingubo ezifana ne-zinc plating okanye i-galvanizing ukunyusa ukuxhathisa ukubola, ngakumbi kwiindawo ezinobungozi.

- Ubungakanani kunye noHlobo: Qinisekisa uhlobo lwe-fastener kunye nobukhulu bulungelelaniswa nesicelo, kubhekiselwa kwimigangatho ye-ASTM yokuqinisa ukuchaneka.

- Imiba yoMsebenzi oPhambili: Qwalasela idiameter yebholithi, idigri yokulinganisa, kunye namandla okuqina, njengoko oku kunempembelelo enkulu ekusebenzeni kokucheba kunye nomthamo womthwalo.

- Iimeko zokusingqongileyo: Vavanya izinto ezifana nobushushu, uxinzelelo, kunye nokubola ukuze uqinisekise ukuba izibophelelo zinokumelana nemiceli mngeni yokusebenza.

Ubuchule bofakelo obufanelekileyo bukwadlala indima ebalulekileyo ekwandiseni ukusebenza kakuhle kweebhawudi zengoma kunye neendibano zenut. Ngokomzekelo, ukusebenzisa amantongomane aphindwe kabini okanye ukuqiniswa kwentwasahlobo kunokunceda ukulawula ukulahleka kwe-pretension, ukuphucula ukuthembeka kwexesha elide.

Iingcebiso zokuGcinwa koMsebenzi oLungileyo

Iindlela zogcino olusebenzayo zibalulekile ekuphuculeni ukusebenza kunye nobomi beebholiti zengoma kunye namantongomane. Ukuhlolwa rhoqo kunye namanyathelo asebenzayo kunokuthintela ukusilela okunexabiso elikhulu. Iingcebiso eziphambili zokulungisa ziquka:

- Cwangcisa uHlolo lwarhoqo: Jonga izinto zokuqhobosha ukuze ubone iimpawu zokuguga, ukubola, okanye ukukhulula.

- Gcina iiRekhodi ezineenkcukacha: Gcina iilog zemisebenzi yogcino ukuze kulandelelwe iintsingiselo zentsebenzo kunye nokuchonga imiba eqhubekayo.

- Ukuxhobisa abaSebenzisi: Qeqesha abasebenzi ukuba baqaphele iimpawu ezilumkiso zakwangoko zokusilela kwe-fasteners, ezifana nokungcangcazela okungaqhelekanga okanye ukulungelelaniswa kakuhle.

- Ukusetyenziswa kweTekhnoloji: Sebenzisa isoftware yokugcinwa kwezithuthi okanye uhlalutyo lweCMMS ukujonga ukusebenza kwe-fastener kunye nokulungelelanisa iishedyuli zokulondolozwa ngokufanelekileyo.

- Tyala kwizixhobo ezihlakaniphile: Sebenzisa i-torque wrenches kunye nezinye izixhobo ezichanekileyo zokuqinisekisa ukuqiniswa okufanelekileyo ngexesha lofakelo kunye nokugcinwa.

Izicwangciso zokukhusela zokulondoloza, ezifana noLawulo lokuSebenza kwe-Asethi (APM), zigxininisa ukuqokelela idatha kunye nohlalutyo oluqikelelweyo. Ezi ndlela zinceda ekuchongeni ukungasebenzi kakuhle kunye nokwandisa iishedyuli zolondolozo, ukuqinisekisa ukuba iikhareji zangaphantsi zangaphantsi zisebenza ngokukhuselekileyo nangempumelelo.

Ingcebiso: I-automatic undercarriage washers inokunciphisa ixesha lokugcina kunye nokuphucula imveliso ngokuphelisa imisebenzi yokucoca ngesandla.

Iibholiti zomkhondo wokuqina ophakamileyo kunye namandongomane zibalulekile ekuqinisekiseni ukhuseleko, ubukho bexesha elide, kunye nokusebenza kakuhle kweekhareji zangaphantsi ezirhubuluzayo. Indima yabo ekugcineni ingqibelelo yesakhiwo kunye nokunciphisa iindleko zokulondoloza ayikwazi ukugqithiswa.

Utyalo-mali kwiiifasteners ezikumgangatho ophezuluiphucula ukusebenza kwezixhobo kwaye icuthe ixesha lokuphumla, inikezela ngogcino lweendleko zexesha elide kunye nokuthembeka kokusebenza. Khetha ngobulumko ukuze ufumane iziphumo ezihlala zihleli.

FAQ

Yintoni eyenza i-bolts ephezulu yamandla kunye namantongomane ahluke kwiifasteners eziqhelekileyo?

Iibholiti zomkhondo eziphezulu kunye namantongomanesebenzisa izinto eziphambili njengentsimbi yealloyi. Baxhathisa imithwalo enzima, ukungcangcazela, kunye noxinzelelo lwendalo, ukuqinisekisa ukuqina kunye nokuthembeka kwizicelo ezifunayo.

Kufuneka zihlolwe kangaphi iibholithi kunye namandongomane?

Hlolaumkhondo iibholiti kunye namantongomanerhoqo 500-1,000 iiyure zokusebenza. Ukuhlolwa rhoqo kunceda ukuchonga ukuguga, ukubola, okanye ukukhulula, ukuthintela ukungaphumeleli okungalindelekanga kunye nexesha lokunciphisa iindleko.

Ngaba iibholiti zamandla aphezulu kunye namandongomane zinganciphisa iindleko zolondolozo?

Ewe, ukuqina kwazo kunciphisa ukutshintshwa kunye nokulungiswa. Oku kuthembeka kunciphisa iindleko zokulondolozwa kunye nokuphazamiseka kokusebenza, ngakumbi kumashishini afana nemigodi kunye nokwakha.

Ixesha lokuposa: Apr-27-2025